Domestic and abroad aluminum raw extract is obtained from different types of raw material preparation team of experts from the field will be tailored to condition stacked melting furnaces.

The aluminum and its standards report to show up with international specifications features which is conforming semi-aluminum manufactured at the high capacity ovens.

Raw materials were prepared to melting, afficient and high-quality melt the alloying with the reverberatory furnace which has high melting technology in our induction and rotary kiln.

Reverberatory furnaces are widely used to melt secondary aluminium scrap for eventual use by die-casting industries.The reverberatory furnaces has a deep bottom portion,side walls,front and rear walls and ceiling.Reverberatory furnaces is shaped like a rectangular prism.Disposed on the front wall works with burners.Long flame fuels(gas,oil or pulverized coal)is used.The material charging of flames desirable licking.Ceiling, is heated by heat supplied by the flame and the charge is heated by radiation.There is very little reaction during the charge in the furnace with fuel and combustion products.Fuel is used to provide the heat required in the oven and it passes through the heat procured charge more radiation.

Each casting is rigorously been tested in the lab’s who are filled with the advanced quality control equipment of the firm.

It is a metal with different dimensions, weights and degrees of aluminum purity. It is generally used by melting and casting in order to obtain different products. A5 – A6 – A7 – A8 grade aluminum ingots can be supplied as T-Bar, ingot and ingot, depending on the usage and transportation needs within the ALM Aluminum Market.

A7 P1020A aluminum, aluminum with a minimum of 99.7% purity

A8 P0610 aluminum, aluminum with a minimum of 99.8 % purity

A5 aluminum alloy, In this alloy class, Al 99.50 and 0.50% Fe,Si,Cu values are contained in the alloy

.

A6 aluminum alloy, In this alloy class, Al 99,60 remaining 0,40% Fe,Si,Cu values are contained in the alloy.

Standard Aluminium Profiles

Aluminium U Profiles

Aluminium T Profiles

Aluminium H Profiles

Aluminium Flat Bar Profiles

Aluminium Rectangular Profiles

Aluminium Rods

Aluminium Angled Profiles

Aluminium Pipe Profiles

Aluminium Box Profiles

Aluminium Coil

Alloys : 1xxx, 3003, 3005, 3105, 5005, 5754

Temper : 0, H1x, H2x

Thickness : 0,2mm – 4mm

Width : Max 1.500mm

Coil OD : Max 1.800mm

Coil ID : 150mm – 508mm

Coil Weight : Max. 9500kg

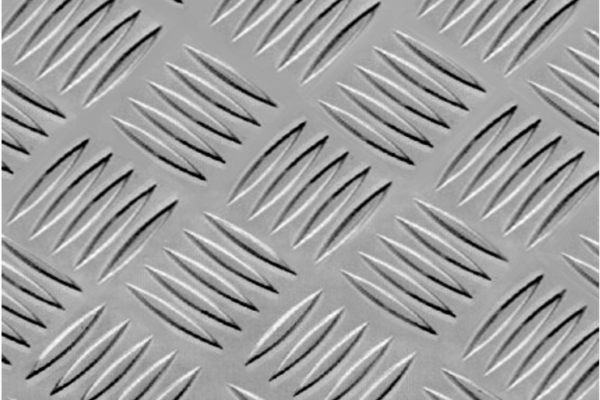

Tread Plate

Alloys : 1050

Temper : H18, H244

Thickness : 1 mm – 3 mm

Bar Height : 1 mm